Introduction

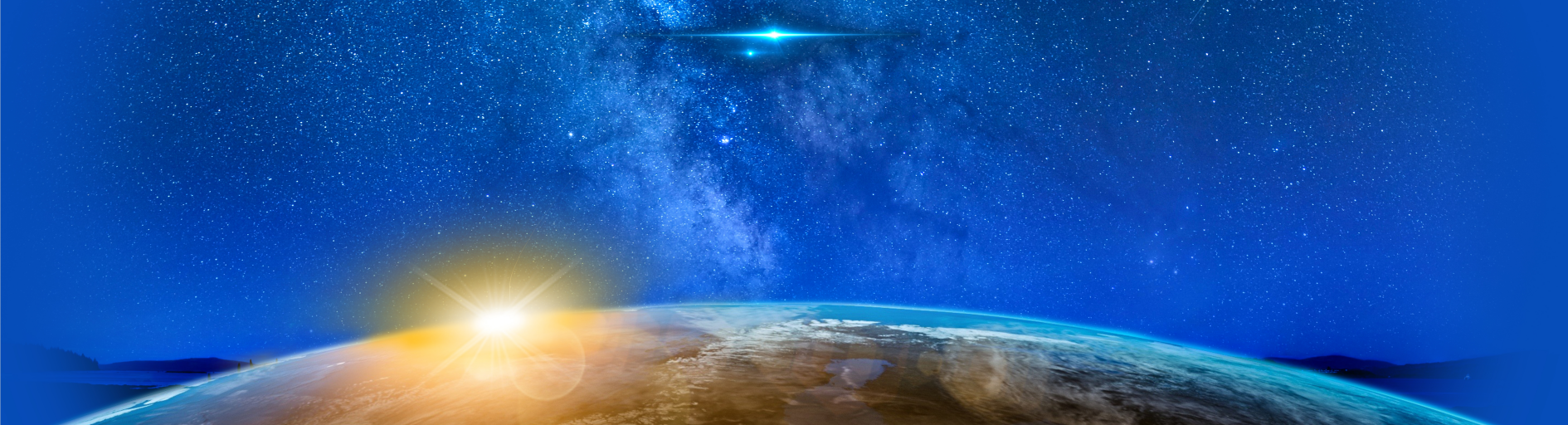

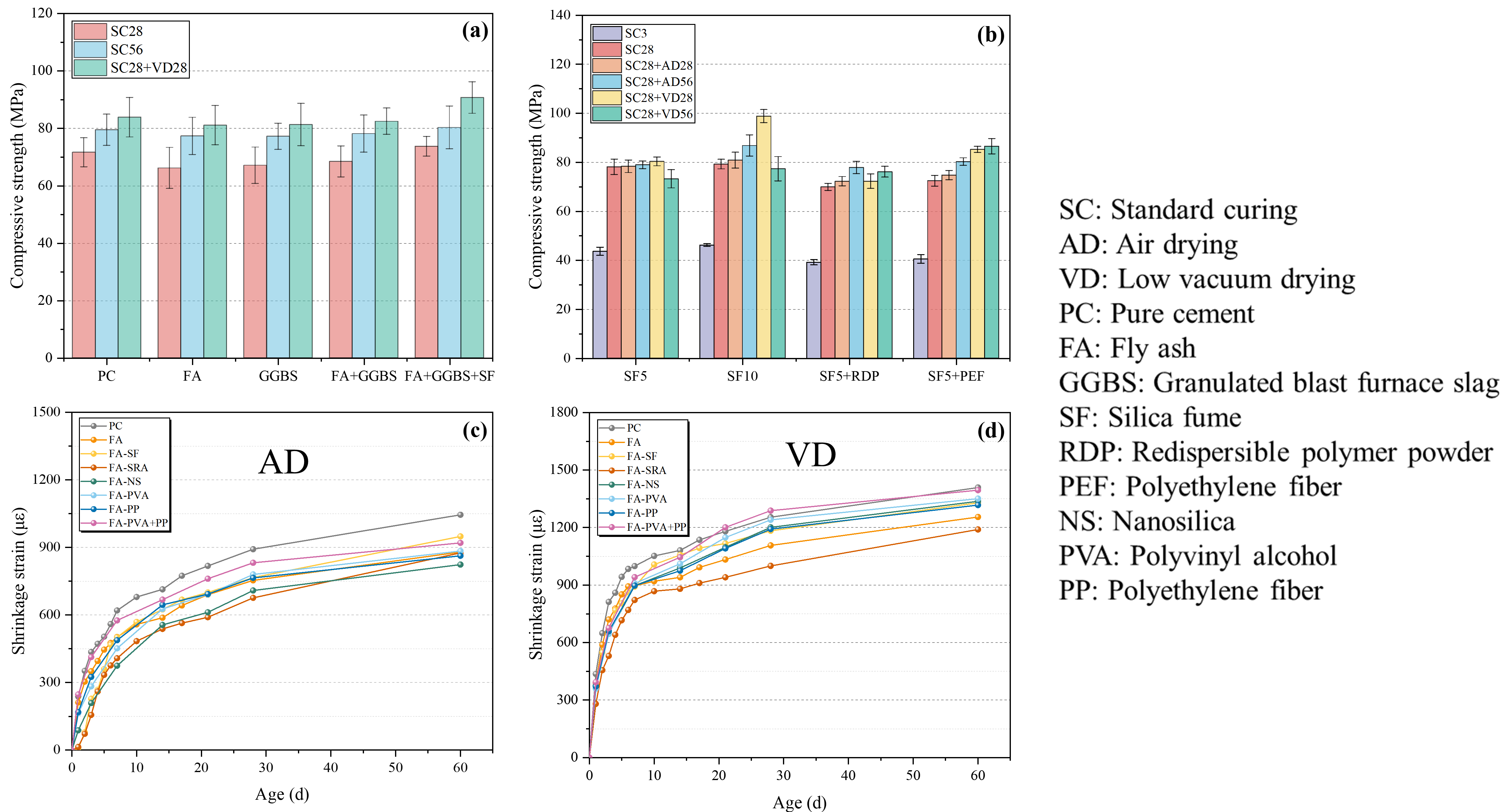

In the lecture, Prof Long discussed the current state of technologies for developing new infrastructure, such as ultra-high-speed low-vacuum tube maglev transportation systems. Focusing on concrete materials used in low-vacuum tube beams, he compared conditions of 60% relative humidity drying and 60°C oven drying to investigate the drying characteristics of cement-based materials in low vacuum environments (100 Pa). Through experimental data and theoretical analysis, he briefly introduced the impact of low vacuum environments on the mechanical properties, deformation performance, and permeability of concrete, as well as the underlying mechanisms. Techniques for improving the performance of cement-based materials in low vacuum conditions, including the use of polymers, modified asphalt, and polymer fibers. Additionally, Prof Long emphasized the impact of low vacuum environments on the phase and microstructure of concrete, aiming to help the academic and engineering communities better understand the evolution of these properties.

He highlighted that these research findings deepen the understanding of concrete performance in low vacuum conditions and provide support for designing, developing, and applying new infrastructure structures and materials operating under similar complex environmental conditions.

The lecture not only showcased the cutting-edge results of Prof Long's team in concrete under low vacuum conditions but also provided valuable references for researchers in related fields.

Mechanisms of silica fume, re-dispersible latex powder (RDP), and polyethylene fibers (PEF) effects on concrete properties in low vacuum environments