Waste plastic applied to building formwork in Xuchang, Henan

Release time: 2023/12/28 Publisher: original Views:

Introduction

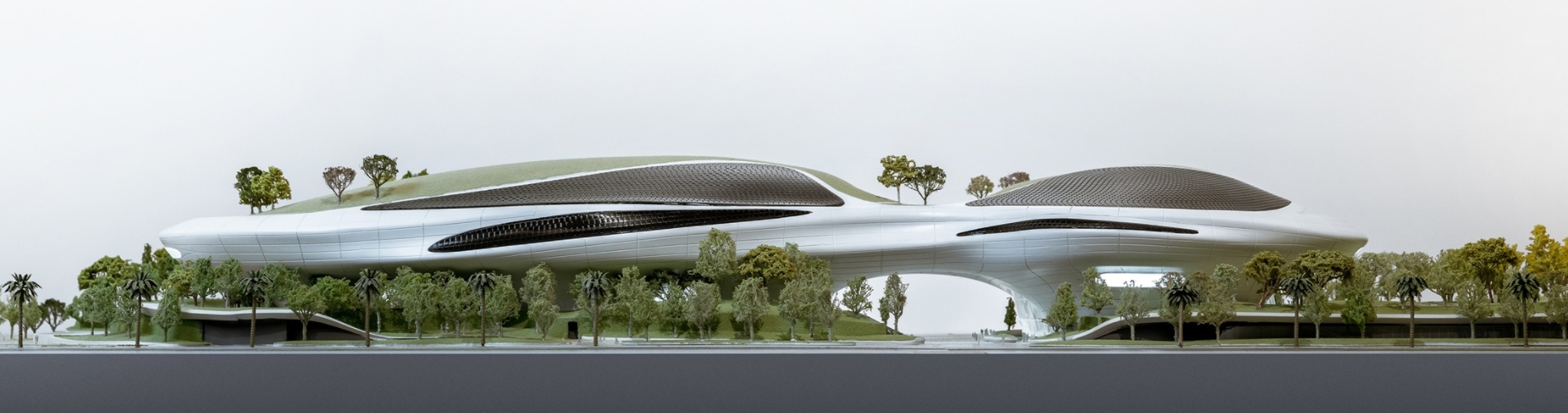

Preparing building formwork with waste polypropylene plastics, the outcome of 2023 NEXCEL Project Standardization and demonstration of preparing building formwork with waste plastics, implemented by China Testing & Certification International Group and Beijing Jiaotong University, has been successfully demonstrated in the construction project in Xuchang, Henan.

Presently, the global volume of waste plastic has reached 6.3 billion tons, posing a severe threat to the ecological environment. Recycling and reusing represent effective measures to address the environmental pollution caused by waste plastic. Polypropylene (PP) plastic formwork exhibit characteristics of recyclability and environmental friendliness. The project team has managed to process waste polypropylene plastic through procedures such as crushing, washing, and modified granulation. As a result, the performance of these materials can rival that of virgin materials. Utilizing granules derived from waste polypropylene plastic, building formwork can once again be produced, with waste plastic being over 50%. Moreover, all performance indicators meet the technical requirements stipulated in JG/T 418-2013 "Plastic Formwork", with a water absorption rate at 0.4%, a bending strength at 52.7 MPa, and a combustion performance rating of B2(E) level.

The waste polypropylene plastic building formworks have been successfully applied to the main buildings at the Ziyuntai project in Xuchang, Henan province, covering an area of 6200 m2. Compared to wooden and steel formwork, waste polypropylene plastic building formwork can save 5% of construction time and reduce comprehensive costs by 58%.

The annual market for plastic formworks in China is 19 million square meters. With the production of 10,000 square meters of plastic formworks requiring around 100 tons of virgin plastic, substituting 50% waste plastic for virgin plastic could annually absorb and dispose of over 90,000 tons of waste plastic, resulting in a reduction of approximately 1.52 million tons of CO2 emissions. The application of this technology has consequently reducing the ecological impact of waste plastics.