Rice University Turns Asphaltene into Graphene for Composites

Time: 2022/12/23 Publisher: oiginal Views:

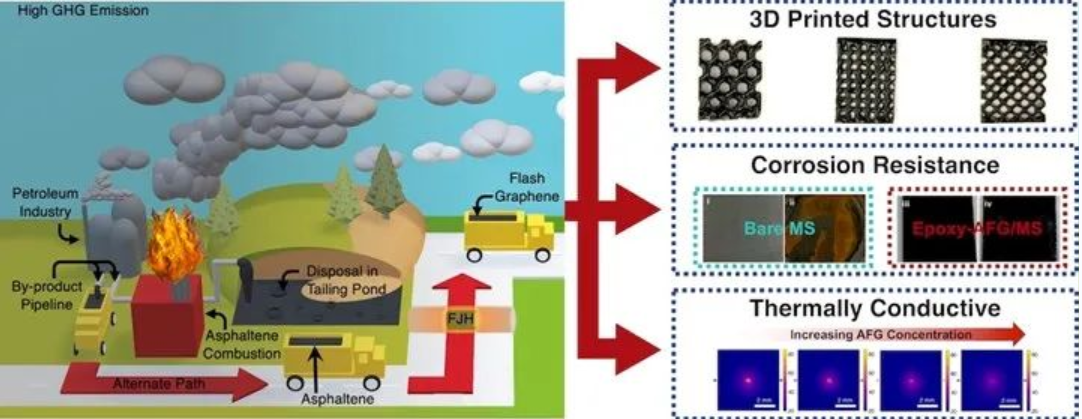

Asphaltenes, a byproduct of crude oil production, are a waste material with potential, according to Rice University (Houston, Texas, U.S.) scientists. Muhammad Rahman, an assistant research professor of materials science and nanoengineering, is employing Rice’s novel flash Joule heating process to convert asphaltenes instantly into turbostratic (loosely aligned) graphene and mix it into composites for thermal, anti-corrosion and 3D-printing applications.

Researchers at Rice are pursuing the “sustainable valorization” of asphaltene by turning it into graphene useful for composite materials

The process is said to make good use of material otherwise burned for reuse as fuel, or discarded into tailing ponds and landfills. Using at least some of the world’s reserve of more than one trillion barrels of asphaltene as a feedstock for graphene would be beneficial for the environment as well.

“Asphaltene is a big headache for the oil industry, and I think there will be a lot of interest in this,” says Rahman, who characterized the process as a scalable and sustainable way to reduce carbon emissions from burning asphaltene.

Asphaltenes are 70-80% carbon already, according to Rahman. The Rice lab combines it with about 20% carbon black to add conductivity and flashes it with a jolt of electricity, turning it into graphene in less than a second. Other elements in the feedstock, including hydrogen, nitrogen, oxygen and sulfur, are vented away as gases.

“We try to keep the carbon black content as low as possible because we want to maximize the utilization of asphaltene,” Rahman explains.

Assured that flash Joule heating process worked as well on asphaltene as it did on various other feedstocks, including plastic, electronic waste, tires, coal fly ash and even car parts, the researchers set about making things with their graphene.