According to a report released by MarketsandMarkets, the global construction FRP market is expected to reach 8.98 billion US dollars by 2026, with a compound annual growth rate of 6.00% in the forecast period. The construction sector has become the most potential application market of fiber composite after automobile and aerospace.

Fiber reinforced composite materials such as glass fiber, carbon fiber and glass fiber reinforced plastic have been widely used as building materials, mainly in structural reinforcement, glass fiber reinforced plastic tiles and glass fiber reinforced extruded profiles. Let's take a look at some famous buildings around the world that use fiber reinforced composite.

Semi-submerged in an undulating dune landscape lies the new Eurojust headquarters in The Hague, the Netherlands.

Wanting to develop a new cost-effective composite façade system for office buildings, construction company TGM involved Indupol, AOC, BÜFA and Solico very early in part design. The successful collaboration has resulted in the creation of novel construction technologies and a great composite façade project example with a unique shape and design. The composite components were made by Indupol through a hand lay-up process in modular molds that were adjusted to the desired shape and dimensions, using resin from AOC and Büfa (delivered through Distributor Euroresins). After molding, the parts were treated with a topcoat in white color and transported to the job site for installation. With minimal use of scaffolding, the parts were lifted by a crane and attached onto the building.

India Calcutta Newtown School

Abin Chaudhuri, the designer of Abin Design Studio, has built a unique landmark for India Calcutta Newtown School. From a distance, each facade looks like a complex Rubik's Cube with letters and mathematical symbols. These structures can bring children a graphical but interesting aesthetic experience.

The facade not only provides shade to the classrooms from the harsh sun but also lends the school a distinct identity. 488 panels, made of Fibre-Reinforced Plastic (FRP), measuring 3.2 x 3.2 meters envelop each of the two academic blocks. 13 different panels were designed with a combination of small and large alphabets, numbers and symbols. These have been placed in various orientations to achieve a randomized effect on the façade. Structural slabs were projected beyond the building surface all around in a way such that an exact number of panels would fit on all surfaces on the symmetrical cuboids. This also enabled simpler servicing of the panels from the back and ensured a better light quality for the building. A small scale study model was created in-house to understand the same and make a decision on treatment of the panels, the walls and the windows behind the screen. A mild steel frame work was devised in a grid like manner on the projected slabs to align with the FRP panels. A fixing detail using steel Z-profiles embedded into the FRP panels was developed to fix these 70kg panels to this M.S. support structure.

The San Francisco Museum of Modern Art (SFMOMA) is one of the largest museums of modern and contemporary art in the United States and a thriving cultural center for the Bay Area. Its new exterior make the largest artistic statement of all, with eye-catching FRP cladding panels on the east façade.

Kreysler & Associates fabricated 700 “rain screen” panels which will cover and help waterproof the 10-story building. When fastened to the aluminum frame, the panels will create a rippling horizontal texture reminiscent of the nearby waters of the San Francisco Bay. The SFMOMA expansion is the largest use of FRP cladding on a multistory building in North America, according to Bill Kreysler, president of Kreysler & Associates Inc. in American Canyon, Calif.

The panels are made from recyclable expanded polystyrene (EPS) foam molds that are milled by a CNC hotwire machine for rough shape and by a five-axis CNC router to create the final double-curved surface. No two panels are alike: Most are 5½ feet wide with lengths varying from six to 30 feet. The skin thickness is only 3/16th of an inch.

The panels are more than just aesthetically pleasing; they perform structurally, too. The building features a cantilever on one side. By using FRP could maximize the span without using additional steel. Also, the rippling of the panels helps stabilize them and significantly reduces the need for reinforcing the metal support frame. “We saved the museum over a million pounds of steel,” says Kreysler.

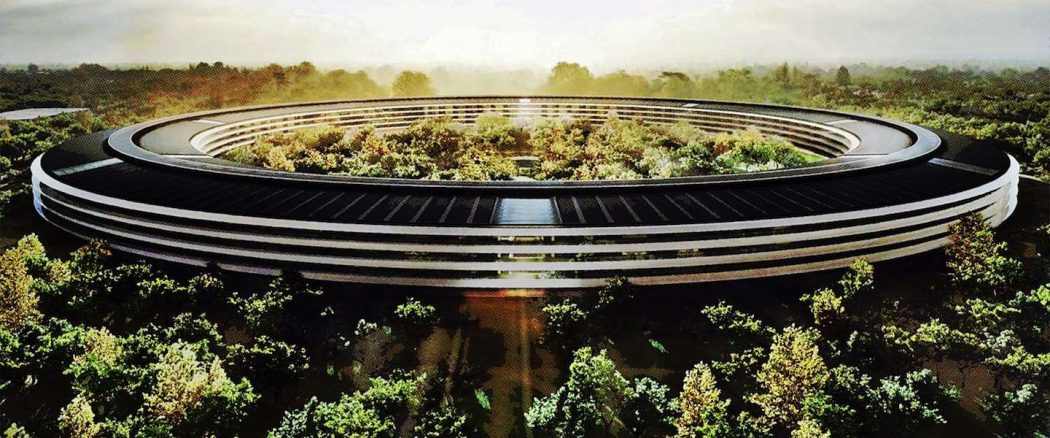

Apple Campus 2

The world's 'largest freestanding carbon-fibre roof' installed on Apple's new $5 billion Cupertino headquarters has been manufactured in Dubai. This massive fiber reinforced polymer (FRP) composite structure makes quite an impression.

With a 14-foot diameter, the floating carbon fiber roof is the largest the world has ever seen. It was built using 44 identical panels that are 70-feet long and 11-feet wide. The entire floating roof weighs approximately 80 tons, which is still a lot lighter than if steel or aluminum had been used.

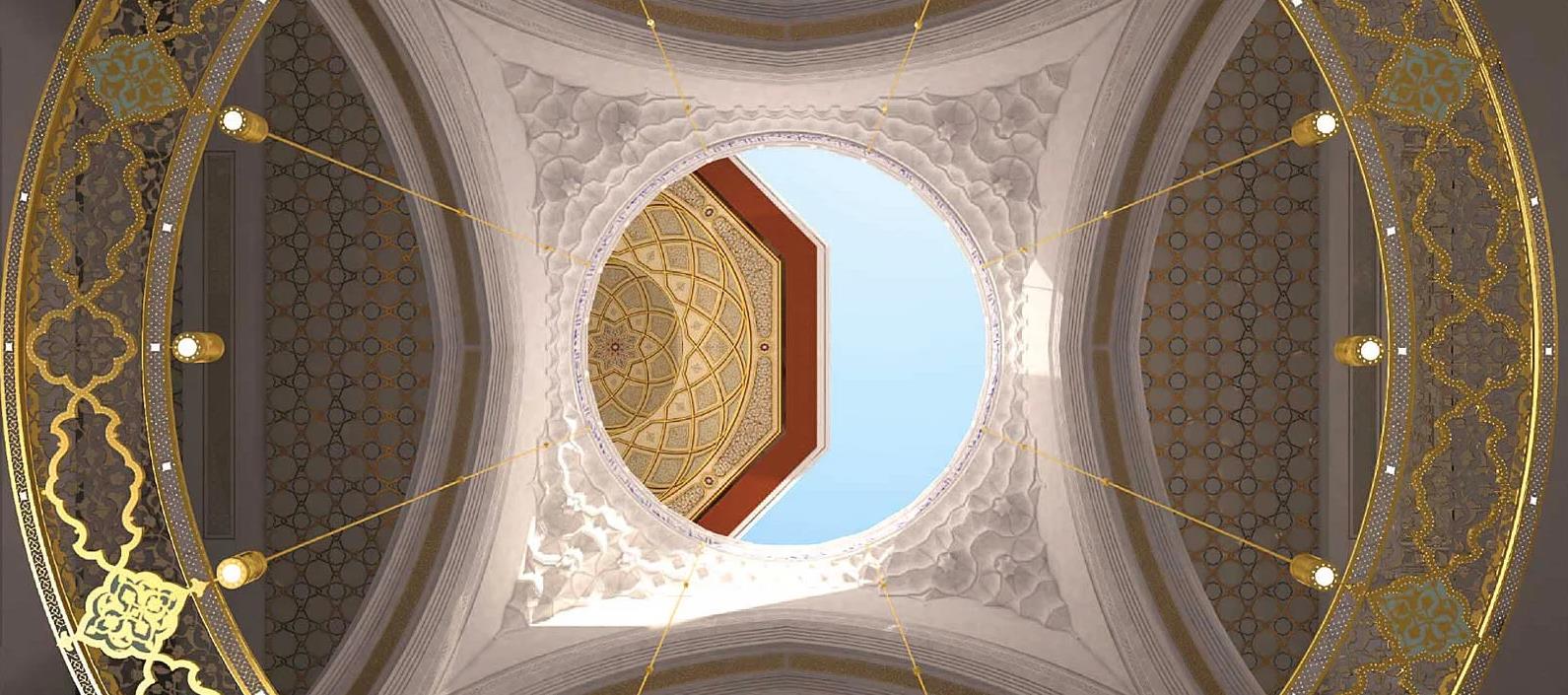

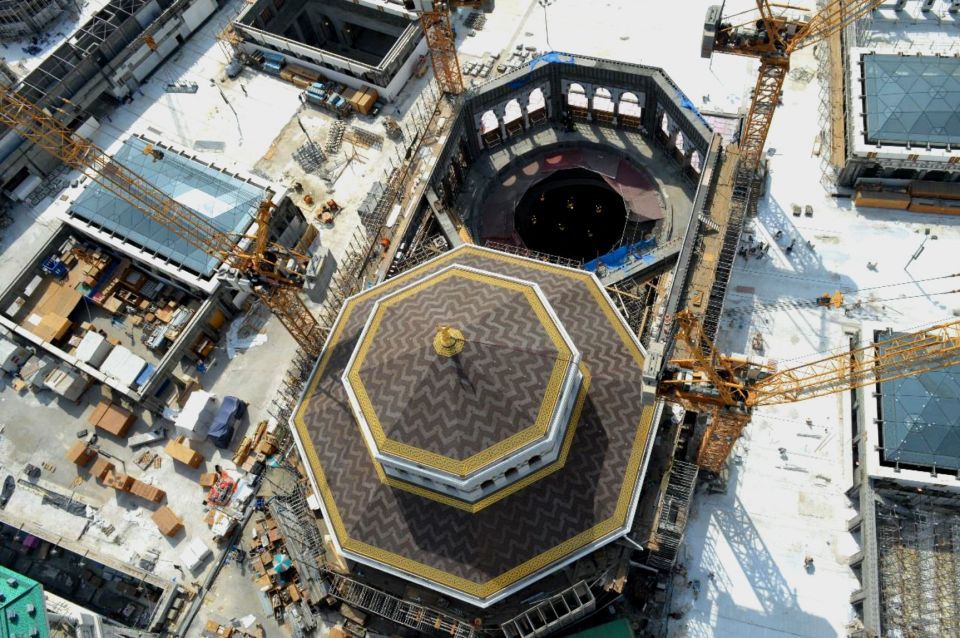

The Great Mosque of Mecca

Dubai-based Premier Composite Technologies (PCT), which built the world's 'largest sliding ceremonial dome on a mosque in the world' in Saudi Arabia.

Speaking to Arabian Business, PCT's principal architect Gabi Bohm confirmed that the ceremonial dome of the 'The Great Mosque of Mecca' includes an octagonal-shaped roof, 38-metres in diameters, which can be moved over the roof deck for natural ventilation in the mosque. The internal and external composite panels on the dome are supported by a steel frame, while the weight of the entire dome, including the boogies and outer cladding, is 800 tonnes. The roof structure, which was built in Dubai, and then shipped and assembled in Makkah, comprises composite panels fixed to a structural steel frame that is supported on four electric wheel drives, Bohm said.

Dubai's Museum of the Future

Sicomin supports advanced fiberglass industries in large scale adaptable mould composite project for Dubai's Museum of the Future interior. Sicomin supplied its innovative bio-based intumescent gelcoat and fire-retardant laminating resins for the production of over 200 double curved panels making up the interior of the Museum's entrance lobby.

The Museum of the Future, a stunning new addition to Dubai’s skyline by architects Killa Design, engineers Buro Happold and contractor BAM International, opened on 22nd February 2022 and features a large percentage of composite materials in the interior construction.

Advanced Fiberglass Industries (AFI) manufactured 230 double curved interior panels, a unique double-helix DNA structure staircase that scales the full seven levels of the museum and 228 GRP oval shaped light structures for the museums car parking area.

Lightweight, quick to install, durable and highly formable fire-retardant composites provided the optimum material solution for the torus shaped Museum’s double curved interior panels that were decorated with a unique raised calligraphy design featuring quotes from His Highness Sheikh Mohammed bin Rashid Al Maktoum, Vice-President and Prime Minister of the UAE and Ruler of Dubai.

In a first of its kind for a large scale composite project, adaptable mould technology from Danish company Adapa, was introduced by Advanced Fiberglass Industries, Dubai (AFI) to ensure that the interior panels could be delivered in line with the project schedule. As well as allowing each unique panel shape to be rapidly configured without the machining of traditional moulds, the adaptive mould technology massively reduced waste generated in the moulding process, contributing to the building’s low carbon LEED platinum credentials.

With a challenging structural and fire safety specification defined, Sicomin’s bio-based SGi128 intumescent gelcoat and SR1122 fire retardant laminating epoxy were chosen for the panels, an additional advantage being that in addition to high fire properties, SGi 128 is also formulated with over 30% carbon from renewable sources, reducing the final carbon footprint significantly.

Sicomin worked alongside the panel manufacturer, providing technical support for the fire test panels and the initial Adapa moulding trials. As a result the high-performance fire-retardant material solution was approved by Dubai Civil Defence, as well as achieving Class A (ASTM E84) and B-s1,d0 (EN13510-1) classifications in the testing carried out by Thomas Bell-Wright.

The Russian Orthodox spiritual and cultural centre, named the 'Holy Trinity Cathedral', is a stunning addition to the 7th arrondissement in Paris. Sicomin delivered a complete package of composite materials to produce both moulds and parts for the 5 gilded domes.

Sicomin supplied materials for the dome tooling to Décision SA, a Swiss based Carboman Group company, who infused a set of glass fibre multiaxial fabric and balsa reinforced moulds using Sicomin's SR8100/SD7820 cost effective 120°C Tg epoxy infusion system. The dome panels themselves were produced at Multiplast's factory in Vannes, France using Sicomin's SR8100/SD4772 epoxy infusion system and a specially developed glass fibre reinforcement lay-up. By combining their heavyweight quadaxial fabric style QX1180 with a woven 500gsm fabric, Sicomin was able to provide a laminate with no print through and excellent top surface flow characteristics to prevent dry spots.

Using a Sicomin composite material solution for the domes had many advantages for this project. The domes light weight allowed for rapid installation as well as reducing the dead loads that must be carried by the building structure. Another benefit of building the domes off site was that both manufacture and decoration of the domes could be carried out in controlled conditions without the weather impacting the production process. Sicomin carried out extensive DSC testing in their laboratory to optimize the post curing procedure to ensure the stability of the finished parts before craftsmen applied 86,000 leaves of real gold to the 640m2 surface area of the domes.

Lucas Museum of Narrative Art

The Lucas Museum of Narrative Art (Los Angeles, Calif., U.S.) will be set on a base isolation system made entirely of glass fiber-reinforced plastic (GFRP), which suits both the institute's curvilinear facade, and protects it in the event of an earthquake. In the design and construction of the Lucas Museum of Narrative Art in Los Angeles, a filmmaker has provided the vision that's leading a team of innovators to push the boundaries on what's possible in architecture. That vision is clad in 1,500 GFRP panels – each one a unique shape.

Global design firm Stantec serves as the architect of record for the museum. When completed, the museum will resemble a cloudlike sculpture that stretches 700 feet long and 270 feet wide over portions of an 11-acre site in LA's Exposition Park. Its sleek, futuristic exterior will be achieved with a rainscreen made of GFRP panels, each one averaging 8x30 feet.

Composites allowed for far bigger panels than would have been constructible in stainless steel, resulting in a more seamless aesthetic. GFRP was lighter than stone or precast cladding, making it not only easier to install but also a better choice for a building in a seismic zone. Early tests also revealed it was easier to create curvatures in two different directions on a large GFRP panel compared to any other option.

The GFRP panels are not only complex, but there's a lot going on behind the smooth façade. The building begins with a geometric structure – straight steel columns and beams that create an angular geometry. That structure is then clad in a weather wall made up of insulation and a waterproof barrier, which is connected to the GFRP rainscreen by a secondary structure of trusses. Those 5,600 uniquely shaped trusses serve as a translator, of sorts, between the angular primary structure and the more fluid GFRP skin.

Kolon One & Only Tower

Morphosis marked the recent opening of the new 820,000-square-foot research and development (R&D) facility for The Kolon Group, the leading textile manufacturing company in South Korea. The design features flexible laboratory facilities, administrative offices, and active social spaces that encourage greater interaction and exchange across the company departments, with a visually striking façade that demonstrates Kolon's commitment to innovation, technology, and sustainability.

"The new research and development facility for Kolon sets the standard for sustainable design and construction in the emerging Magok district," said Project Principal Eui-Sung Yi. "Inspired by Kolon's severe-weather layered performance wear, our team worked with engineers and fabricators to apply a performance driven series of vertical layers to our design that challenges the conventional approach to sunshade design and enhances the building's sustainability."

The distinctive brise-soleil system on the main, west-facing façade of the building was created through a complex process early in the design development phase of the project, resulting in a unique sunshade that is both performative and symbolic. The design of the façade features an interconnected array of sunshades that form the monolithic, outer skin, analogous to a woven fabric—a reference to Kolon's research in textiles, as well as a symbol of collaboration between the company's many departments.

The units of the sunshade are parametrically shaped to balance shading and views and are made from fiber reinforced polymer (FRP) using one of Kolon's own high-tech fabrics, Aramid, to dramatically increase the material's tensile strength. One of the most notable features of the design is the lack of a visible support structures, allowing the sunshade to seemingly float outside the glazed wall and providing clear views from the interior spaces.

Roof terraces and courtyards provide increased access to natural light and fresh air to invigorate the work environment. Other sustainable measures include green roofs, photovoltaics (PV) and geothermal design, recycled materials, and utilizing a bubble deck slab that reduces the amount of concrete used by 30 percent.

As part of the Shanghai Disney Resort in China, Tomorrowland is a FRP composite wonder. It is the resort's newest of 6 parks and spans over 25,000-square-feet of land. Tomorrowland were constructed from fire retardant (FR) gelcoated FRP composite moulded parts in several hundred different shaped and sized components.

The FRP composite parts supplied included facades, passenger sections of the Tron roller-coaster, parts of the Buzz Lightyear ride, the Lilo & Stitch Theatre, outdoor dining furniture and exterior cladding on the concourse and surrounding facilities. Settling on curved FRP composites, the designers was able to create a trio of attractions all with a futuristic aesthetic. From concourse base cladding to cosmetic panels, FRP composites can be found in 12 different locations throughout Tomorrowland.